Turning is the process of machining a piece of metal to the required shape by removing part of the metal, known as swarf.

The turning process is particularly used to make objects such as the feet of tables and chairs, door handles and knobs, bolts and screws. Let’s take screws as an example: the typical feature of these objects, the thread, is obtained by sheet metal turning.

The lathe

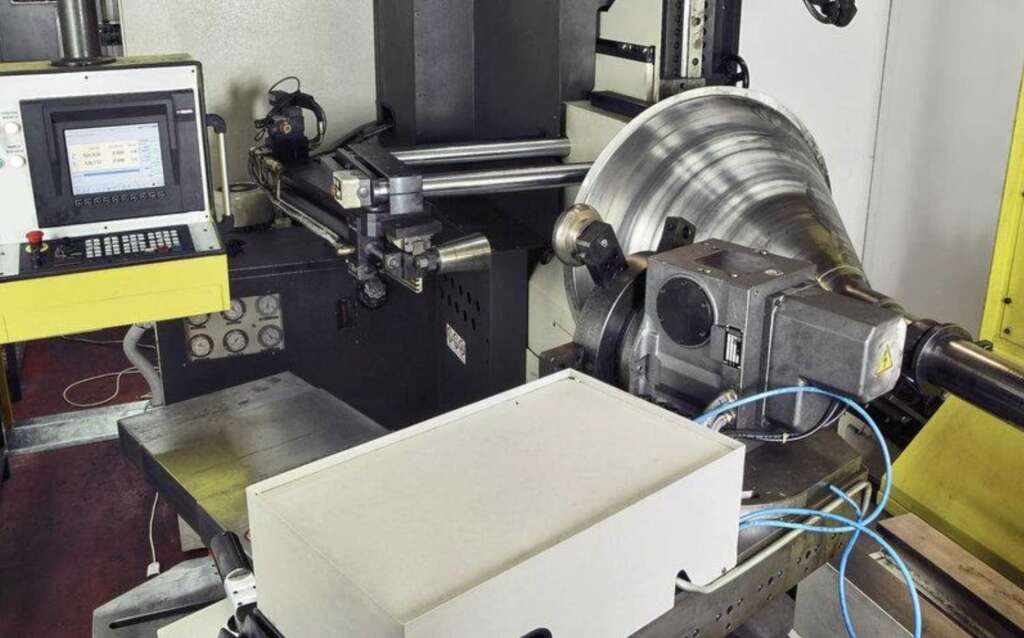

Turning gets its name from the machinery required to carry out this operation, namely the lathe. Various types exist, but the operational concept is similar.

In most cases, the lathe has an electrically driven motor that creates a rotary motion transmitted to the drive head. A spindle is installed on this drive head, which holds the piece to be turned throughout the entire turning process. To the right of the spindle, a sliding carriage is installed on which the tool turret is mounted. It is designed to hold all the tools that will be used to cause friction on the rotating piece supported by the spindle. Different types of tools can be used depending on the type of work and deformation of the piece to be obtained.

Phases in the turning process

The turning process consists of two phases. In the first, the material is roughly removed, whereas in the second, the piece is shaped down to the minutest detail to obtain the required shape and size.

Turning at Pesce Metal Factory

Pesce Metal Factory has a state-of-the-art fleet of machines, including different types of lathes.This allows us to perform a wide range of turning processes, resulting in customised pieces that meet high standards of quality.

Do you require further information? Contact us