Each type of metal is worked using dedicated processes, selected for the intrinsic features of the metal itself and depending on the result to be obtained in terms of aesthetic appeal and performance.

In this article, we will describe sheet metal turning, a process used to shape mainly iron, copper, brass and aluminium, as well as some special alloys such as stainless steel.

SHEET METAL TURNING

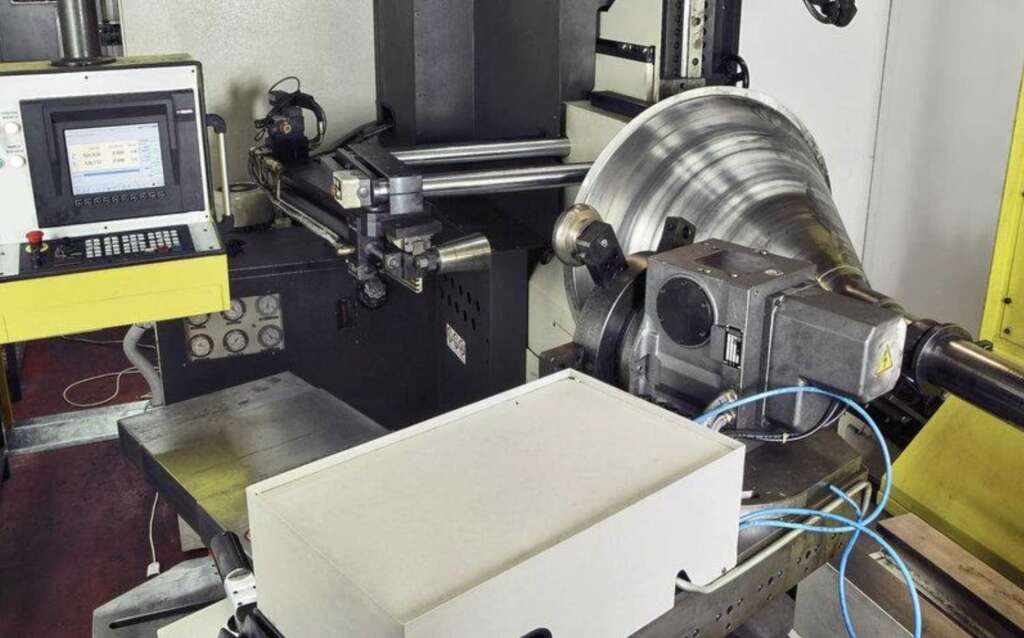

Sheet metal turning is carried out with a metal sheet that is cut into the shape of a disc on a special disc-cutting machine, and then deformed using lathes and presses.

Once the die is assembled on the lathe, the metal is then fixed with a tailstock and rotated on the spindle. Then, using lathe tools, the sheet metal is pressed against the die and shaped. With sheet metal turning, metal discs up to an initial diameter of 1400 mm can be processed.

ADVANTAGES OF SHEET METAL TURNING

Sheet metal turning offers countless advantages:

- robustness and durability, as the end product is seamless (no welding)

- high-quality finishes

- option of producing small batches

- cost-effectiveness

- quick start to the production process

In order to guarantee its customers an excellent service in a short and flexible time, Pesce Metal Factory’s fleet of machines includes manual and semi-automatic lathes, assisted by the expert hands of highly specialised workers. Experience and continuous training are essential for making the best use of the most innovative technologies and offering increasingly original and sophisticated solutions.