Project Description

METAL CARPENTRY

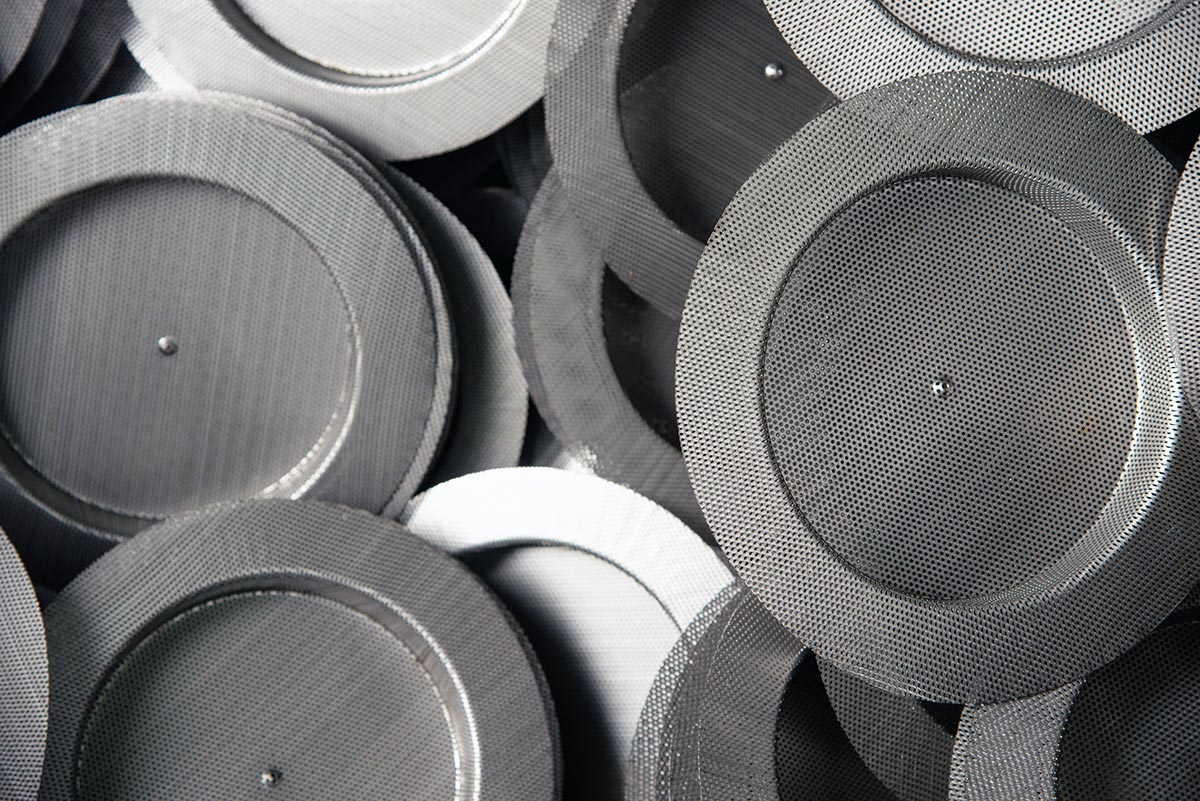

Pesce Metal Factory specialises in metal carpentry, in particular in metalworking processes such as metal turning, metal cutting and metal spinning. Our products are employed in different industries, from Agricultural Machinery, to Furniture Design.

METALCARPENTRY & METALWORKING

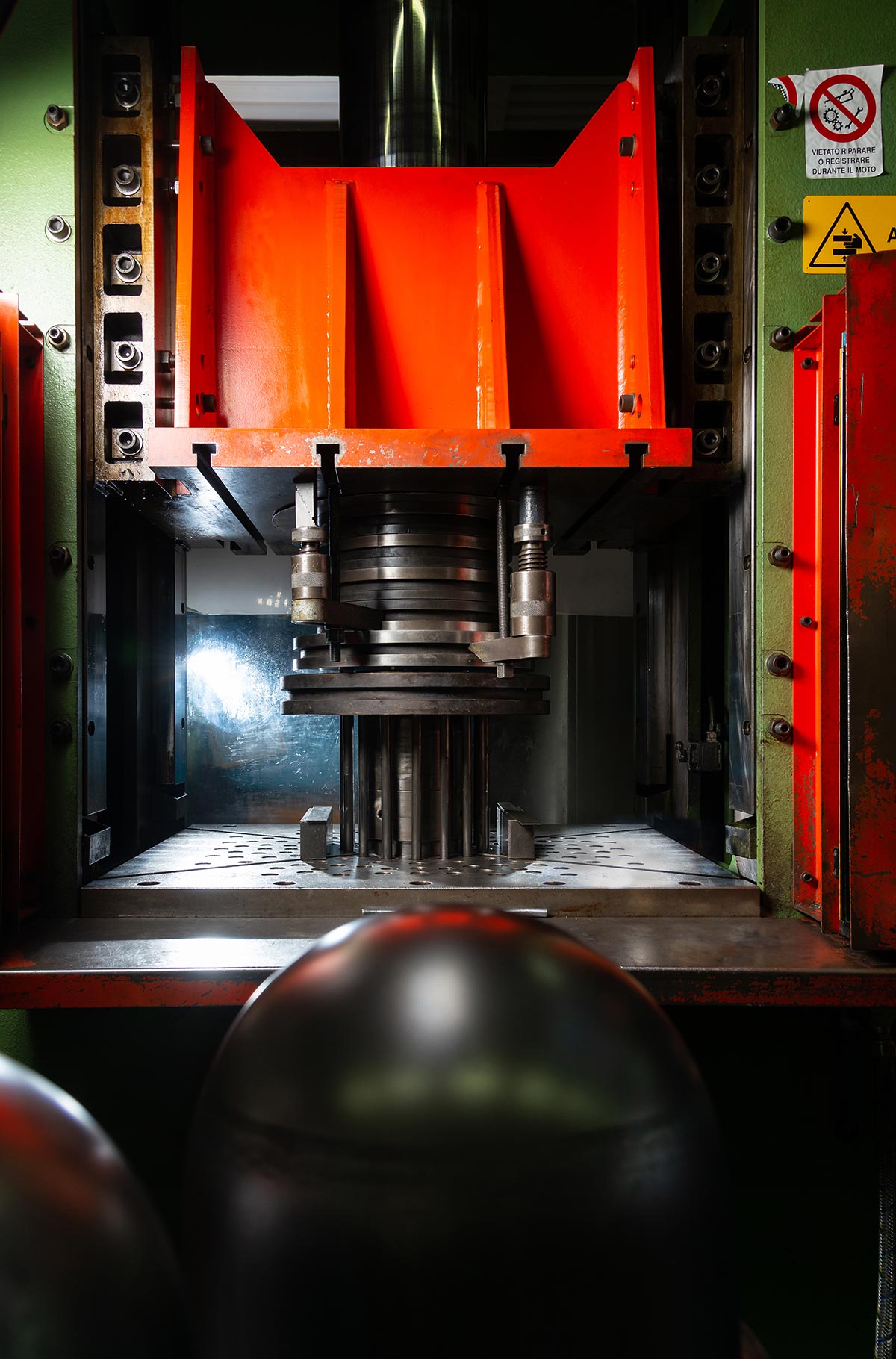

The processes involved in metal carpentry production include:

- Bending: We bend metal sheets up to 3 meters long. We have available CNC press brakes which offer high working flexibility and bending precision in order to combine versatility and performance to satisfy all customer needs

- Pressing: Production Know-how allow to shape every type of metal (stainless steel, brass, copper, aluminium, iron) in different thickness and size for several applications, from industrial manufacturing to high quality products. Pesce Metal Factory have available an extended pressing inventory (automated and hydraulic machineries), with maximum power of 300 tons and 1000×800 mm work platform

- CNC calendering

- Welding: we execute TIG and MIG weldings on materials like iron, aluminium and stainless steel

- CNC beading

- Guillotine shears of metal sheets up to 6 mm thickness

- Hole drilling, threading and countersink

- Riveting

- Stud welding on iron, aluminium and stainless steel