Project Description

CNC punching and 2D/3D LASER CUTTING

2D/3D laser cutting is one of the processes that Pesce Metal Factory makes available to its customers.

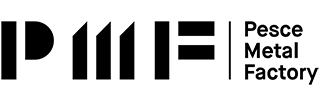

The laser cutting process uses a beam of light emitted by a special lens that heats sheet metal until it melts and cuts it. The laser beam then follows the set cutting path.

THE PROCESS

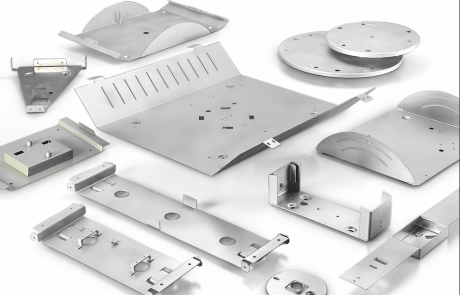

The company uses this process to cut iron, steel, aluminium, copper and brass. The cut pieces can reach a thickness that varies depending on the material:

- 20 mm for iron

- 10 mm for steel

- 8 mm for aluminium

- 6 mm for copper and brass

Unlike 2D laser cutting, which allows shapes to be obtained from flat sheet metal, in 3D laser cutting, three-dimensional cutting is performed on parts already deformed by bending, pressing or turning.

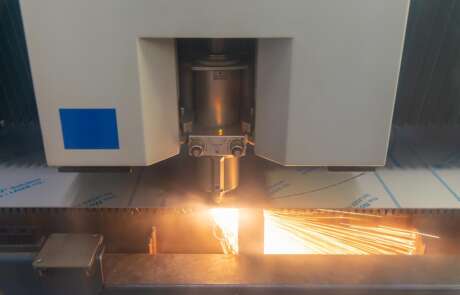

Moreover, thanks to combined technology of laser-film and CNC punching, it’s possibile to integrate in a single machinery several working processes, such as laser cutting, CNC punching, pressing, roll deformation, threading and countersink in order to optimize the whole production system.

All the pieces machined by laser cutting undergo strict quality control and appropriate storage.